Suppose you're looking to improve your vehicle's handling and achieve that perfect stance. In that case, learning how to install aftermarket coilovers can save you hundreds of dollars in labor costs while giving you complete control over your suspension setup. This comprehensive guide walks you through the entire process—from selecting the right spring rates to post-installation alignment—so you can tackle this intermediate-level project with confidence.

Installing coilovers typically takes 4-6 hours for a DIY enthusiast with basic mechanical knowledge. While the process requires patience and the right tools, the rewards are significant: adjustable ride height, improved cornering performance, and a personalized driving experience that factory suspension simply can't match.

Key Takeaways

- Professional alignment is mandatory after coilover installation to prevent tire wear and ensure safe handling

- Spring rate selection depends on vehicle weight, intended use, and personal preference (daily driving vs. track use)

- Break-in period matters: Drive gently for the first 50 miles and re-torque all fasteners

- Ride height adjustment should be done gradually—start conservative and lower incrementally

- Proper tools are essential: A quality torque wrench and jack stands rated for your vehicle are non-negotiable

- Symmetry is critical: Maintain identical settings side-to-side for balanced handling

What Are Aftermarket Coilovers and Why Upgrade?

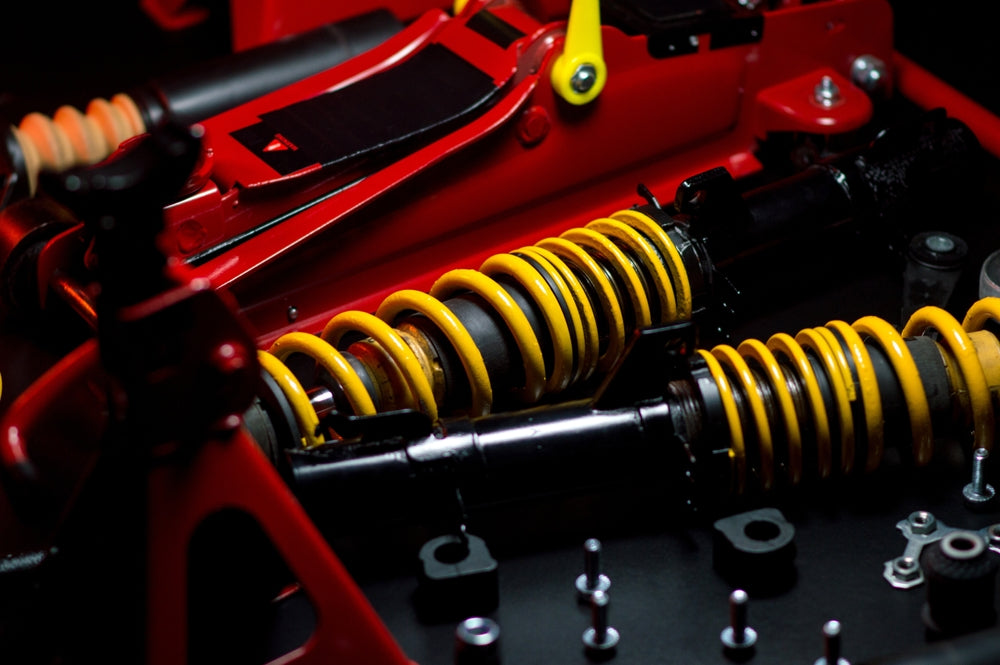

Aftermarket coilovers combine a shock absorber and coil spring into a single, adjustable unit that replaces your factory suspension components. Unlike lowering springs that work with stock shocks, coilovers offer complete control over ride height and damping characteristics.

The benefits extend beyond aesthetics. Quality coilovers reduce body roll during aggressive cornering, improve weight transfer during acceleration and braking, and allow you to fine-tune your suspension for specific driving conditions. Whether you're preparing for track days or simply want sharper handling on your daily commute, coilovers provide the adjustability that fixed suspension systems cannot offer.

Most enthusiasts upgrade when their factory suspension shows signs of wear—excessive bouncing, poor handling response, or visible shock leakage. However, many upgrade simply to unlock their vehicle's full performance potential and achieve a more aggressive stance.

Essential Tools and Materials for Installation

Do you need special tools to install coilovers? Yes—you'll need a floor jack, jack stands rated for your vehicle's weight, a torque wrench, socket sets, and penetrating oil at minimum. Spring compressors may be required depending on your vehicle.

Before starting your installation, gather these essential items:

Required Tools:

- Floor jack and jack stands (properly rated)

- Torque wrench (with appropriate ft-lb range)

- Socket set and combination wrenches

- Breaker bar for stubborn bolts

- Penetrating oil (apply 24 hours before starting)

- Spring compressor (vehicle-dependent)

Safety Equipment:

- Safety glasses and work gloves

- Wheel chocks

- Adequate work lighting

Materials:

- Complete coilover set (front and rear)

- Anti-seize compound

- Thread locker (blue Loctite)

- Shop towels

Never compromise on safety equipment. Working under a vehicle supported only by a jack is extremely dangerous—always use properly positioned jack stands on level ground.

Choosing the Right Spring Rates

What spring rate should I choose for coilovers? For daily driving, choose spring rates between 6-10 kg/mm (336-560 lb/in) depending on your vehicle weight, while track-focused setups may use 10-14 kg/mm (560-784 lb/in) for reduced body roll and sharper response.

Spring rate—measured in kilograms per millimeter or pounds per inch—determines how much force is needed to compress the spring. Higher rates mean stiffer suspension, which improves handling but reduces comfort. Lower rates provide a smoother ride but allow more body movement.

Consider these factors when selecting spring rates:

Vehicle Weight and Distribution: Heavier vehicles require stiffer springs to control suspension movement. Front-engine cars typically need higher front spring rates due to engine weight.

Intended Use: Daily drivers benefit from moderate spring rates (6-8 kg/mm) that balance comfort and performance. Track-focused builds can handle stiffer rates (10-14 kg/mm) since comfort takes a back seat to handling precision.

Driving Style: Aggressive drivers who frequently corner hard prefer stiffer setups, while those prioritizing ride quality should opt for the softer end of recommended ranges.

Most coilover manufacturers provide spring rate recommendations for specific vehicle models. Start with their baseline suggestions and adjust from there based on your preferences and driving conditions.

Pre-Installation Preparation

Proper preparation prevents problems during installation. Start by measuring your current ride height at all four corners from the ground to the fender lip. Take photos from multiple angles—these "before" shots help you document your work and serve as reference points.

Park on a level surface and gather all tools within easy reach. Clean your wheel wells and suspension components to make the job easier and identify any worn or damaged parts that may need attention.

Before touching your vehicle, prepare the coilovers themselves. Unbox all components and verify everything matches the manufacturer's parts list. Set initial ride height adjustments to mid-range settings—you'll fine-tune later after installation and break-in. Apply anti-seize compound to all adjustment threads now, as it's much easier than doing it during installation.

Review the manufacturer's installation manual thoroughly. Many companies provide detailed videos specific to your vehicle make and model. Watching these beforehand familiarizes you with unique challenges or steps specific to your application.

Step-by-Step Installation Process

Front Suspension Installation

Start by safely lifting the front of your vehicle using proper jack points specified in your owner's manual. Position the jack stands at the designated support points, lower the vehicle onto the stands, and test stability before removing the wheels.

Spray penetrating oil on all mounting hardware—top mount nuts and lower mounting bolts. This simple step can save hours of frustration with seized fasteners.

Support the lower control arm with your floor jack, then disconnect the sway bar end link from the strut. Remove any brake line brackets attached to the strut housing, being careful not to stress brake lines. If your vehicle has ABS sensors mounted to the strut, disconnect them carefully.

Remove the lower strut mounting bolts while supporting the assembly. Move to the engine bay and locate the top mount nuts (typically three nuts under the strut tower). Remove these nuts and carefully extract the entire strut assembly from the wheel well.

Insert your new coilover through the suspension mounting point, starting with the top mount. Hand-thread the top mount nuts without fully tightening—you'll need some movement to align the lower mounting points. Once the lower mounting holes align, install those bolts hand-tight.

Reconnect sway bar end links, brake line brackets, and ABS sensors. Now, torque all fasteners to manufacturer specifications in the proper sequence (typically top mount first, then lower bolts). Repeat this entire process for the opposite side.

Rear Suspension Installation

Rear installation follows similar principles but with some variation depending on your vehicle's design. Sedans and coupes typically have interior access to top mounts through the trunk or rear deck, while some vehicles have externally accessible mounting points.

Lift and support the rear of your vehicle safely, then remove the rear wheels. Locate and access the upper shock mount—you may need to remove trunk trim panels or fold down rear seats.

Support the rear suspension with your floor jack if needed to align mounting points. Remove upper mounting hardware, disconnect any electrical connections (adaptive dampers or height sensors), then remove lower mounting bolts.

Install the new rear coilovers by positioning them in the mounting location, hand-threading upper mounts, aligning lower mounting points (you may need to compress the suspension slightly), and installing lower mounting hardware.

Torque all fasteners per specifications and repeat for the opposite side. Double-check that all electrical connections are secure and all mounting hardware is properly tightened.

Final Steps

Reinstall all four wheels with hand-tightened lug nuts in a star pattern. Carefully lower the vehicle to the ground and torque lug nuts to your vehicle's specifications. Bounce each corner several times to settle the suspension, then re-torque all suspension fasteners after settling—this crucial step ensures nothing loosens during initial driving.

Ride Height Adjustment: Getting the Perfect Stance

How do you adjust coilover ride height? Loosen the locking collar, thread the adjustment collar up to lower the vehicle or down to raise it, maintain equal adjustments side-to-side, then securely tighten the locking mechanism.

Most coilovers use threaded adjustment collars that change ride height by altering spring preload. Start conservative—dropping 1 to 1.5 inches lower than stock provides improved handling without compromising daily drivability. Aggressive drops of 2 inches or more may require additional modifications, like adjustable control arms, to maintain proper suspension geometry.

Measure from identical points on each side of the vehicle to ensure symmetry. Even small differences (1/4 inch) can affect handling and tire wear. Use a measuring tape from the ground to fender lip at the wheel's centerline for consistent measurements.

After adjusting ride height, drive 50-100 miles to allow the suspension to settle. Re-measure and make fine adjustments as needed. Check for tire rubbing at full steering lock and over bumps—if rubbing occurs, either raise the vehicle slightly or address clearance issues.

Common mistakes include dropping too low initially, forgetting to tighten locking collars securely, and maintaining uneven side-to-side heights. Take your time and measure carefully—proper setup prevents problems down the road.

Post-Installation Alignment: Critical for Performance

Do you need an alignment after installing coilovers? Yes, absolutely—professional alignment is essential after coilover installation because lowering your vehicle changes suspension geometry, which affects camber, caster, and toe angles that directly impact tire wear and handling safety.

Skipping alignment is the biggest mistake DIYers make after suspension work. Even if your ride height seems close to stock, the suspension geometry has changed. Driving without proper alignment causes rapid tire wear (potentially ruining tires in just a few thousand miles) and compromises vehicle handling and safety.

Key alignment angles affected by coilovers include:

Camber (tire tilt when viewed from front): Lowering typically increases negative camber, where the top of the tire tilts inward. Moderate negative camber (-1.5° to -2.5°) improves cornering, but excessive camber causes inner tire wear.

Toe (wheel direction when viewed from above): This is the most critical angle for tire wear. Even slight toe misalignment will destroy tires quickly. Most street cars run slight toe-in (wheels pointing slightly inward) for stability.

Caster (steering axis tilt when viewed from side): Less affected by ride height changes, but proper caster ensures good steering feel and return-to-center characteristics.

Find an alignment shop experienced with modified vehicles—not all shops understand performance alignment specifications. Communicate your vehicle's primary use (daily driving, occasional track days, etc.) so they can set appropriate specs. Request a printout showing before-and-after measurements.

Expect to pay $80-200 for alignment, depending on your location and required adjustments. Consider it mandatory maintenance, not an optional expense.

Breaking In Your New Coilovers

Do new coilovers need to be broken in? Yes, new coilovers require a 500-mile break-in period with gentle driving for the first 50 miles to allow seals, bushings, and damping components to properly seat and reach optimal performance.

During the first 50 miles, avoid aggressive cornering, hard acceleration, and rough roads when possible. This allows internal components to wear in properly and ensures longevity. You may notice the ride feels stiff initially—this is normal and will improve as components break in.

At the 50-mile mark, check and re-torque all suspension fasteners, inspect for any leaks or damage, re-measure ride height (some settling is normal), and verify no rubbing occurs at full suspension travel. This is also the ideal time to schedule your professional alignment if you haven't already.

Some creaking or settling noises are normal during the break-in period as components mate together. However, consistent clunking or knocking requires immediate inspection—these sounds may indicate loose hardware or installation issues.

Fine-Tuning Damper Settings

Many aftermarket coilovers feature adjustable damping, allowing you to customize ride quality and handling characteristics. Single-adjustable coilovers control rebound damping (how quickly the shock extends), while dual-adjustable units control both rebound and compression independently.

Start at the manufacturer's recommended baseline (often mid-range adjustment). Make small changes—2-3 clicks at a time—and test drive between adjustments. Keep detailed notes of settings and your impressions, as it's easy to forget what worked well.

Stiffer damping reduces body roll and provides more direct handling feedback, making it ideal for spirited driving or track use. Softer damping improves ride comfort over rough roads and provides better traction on uneven surfaces. Many enthusiasts run softer settings for daily driving and dial in firmer settings for track days or canyon runs.

Adjust front and rear independently to fine-tune balance. If the rear feels too loose during corner exits, increase rear damping. If the front feels harsh over bumps, reduce front compression damping. The key is making one change at a time and testing thoroughly.

Common Installation Problems and Solutions

Even experienced DIYers encounter challenges during coilover installation. Here are solutions to the most common issues:

Seized factory suspension bolts: Spray penetrating oil 24 hours before starting. If bolts still won't budge, apply heat carefully with a torch while protecting nearby rubber components and brake lines. Have replacement bolts available—sometimes cutting stubborn bolts is the only solution.

Top mount alignment issues: Have a helper compress or extend the suspension while you guide the coilover into position. Verify you're installing components in the correct orientation—some top mounts have specific forward/backward positioning.

Post-installation noise: Check all fastener torques first. Verify top mount installation and inspect for any contact between suspension components and chassis. Sometimes dust boots need adjustment or replacement.

Uneven ride height: Confirm coilover adjustment settings match exactly side-to-side. Measure from consistent reference points. If heights remain uneven with identical settings, your vehicle may have pre-existing chassis damage or modifications affecting geometry.

Tire rubbing: Slightly increase ride height, verify wheel and tire sizes are appropriate for your drop, and check alignment specifications. Extreme lowering may require fender modifications or different wheel offsets.

Maintaining Your Coilovers for Longevity

Proper maintenance extends coilover life significantly. Inspect your suspension monthly for leaks, damage, or loose hardware. Clean coilover bodies quarterly with mild soap and water, paying special attention to exposed threads. Apply silicone spray to the adjustment threads to prevent corrosion and ensure smooth adjustments.

Every six months, check all torque specifications and inspect dust boots for tears or damage. Road salt and debris accelerate corrosion, so rinse suspension components regularly if you drive in winter conditions or near coastal areas.

Quality coilovers typically last 50,000-80,000 miles before requiring rebuilding or replacement. Signs of wear include oil leaking from shock bodies, loss of damping control (excessively bouncy ride), or physical damage to components. Many manufacturers offer rebuild services that cost less than replacement while restoring like-new performance.

Transform Your Suspension with Confidence

Learning how to install aftermarket coilovers empowers you to customize your vehicle's suspension precisely to your preferences while saving hundreds in labor costs. While this intermediate-level project requires patience, proper tools, and attention to detail, the results—improved handling, adjustable ride height, and enhanced driving dynamics—make it worthwhile for enthusiasts committed to getting the most from their vehicles.

Remember that professional alignment isn't optional—it's essential for safety, tire longevity, and optimal performance. Take your time during installation, follow torque specifications carefully, and don't skip the break-in period. With proper installation and regular maintenance, quality coilovers will provide years of improved performance and driving enjoyment.

Need Quality Aftermarket Suspension Components?

While PartsMax doesn't carry coilovers, we stock thousands of aftermarket parts to support your automotive projects. From body panels to lighting components, our 250,000 square foot Miami warehouse is stocked with competitively priced parts backed by 25+ years of serving South Florida's automotive community.

Contact PartsMax Today:

📞 Call: (305) 691-1313

🌐 View our online inventory of aftermarket auto parts at Partsmax.com

📍 Visit our warehouse: 3401 NW 73rd ST, Miami, FL 33147

Fast next-day delivery throughout Miami-Dade, Broward, and Palm Beach counties. Please note: PartsMax specializes in parts sales only and does not offer installation or mechanic services.